Industrial fabricators often offer specialized engineering and CAD services as an integral part of their project delivery, extending beyond just the physical construction of components. These services are crucial for transforming initial concepts or client specifications into detailed, ready-to-manufacture designs.

ASMEBPVC Sec. VIII Div. 1 & 2, Sec. II, Sec.IX, Sec. V • TEMA Standard (Class R, C &B) • IS 2825 • PV-Elite

We use following design & development software. • AutoCAD – Autodesk & Creo Parametric (Pro-E) • Draft Sight • APL 650/ API 620 • Customer’ Specification

Welding & Metallurgy : • Welding processes: SMAW, GTAW, SAW, GMAW, Multi process Welding, Corrosion Protection Overlays, Tube to Tube sheet Welding & Expansion • Welders & Operators qualified as per ASME SEC-IX • Our continuous improvement in welding technology has enables us to develop hundreds of welding procedures as per international code. • Our procedures are qualified for variety of materials in thickness range from 2mm to 200mm.

Material Handled : • Stainless Steel : SS304, SS316, SS304L, SS316L, SS316TI, SS317, SS321, SS904L, (UNS N08904) • Exotic material : SS Duplex, Super Duplex, Hastelloy, Inconel • Carbon Steel: SA516 Gr 60, SA516 Gr70, LTCS • Mild Steel: IS 2062 Various Grades as per Requirement.

The engineering component involves applying principles of physics and materials science to ensure the fabrications are structurally sound, efficient, and meet performance requirements. This often includes:

Reviewing existing designs to improve manufacturability, reduce material waste, and lower costs.

Performing calculations to verify that structures can withstand specified loads, environmental factors, and operational stresses. This may involve Finite Element Analysis (FEA) for complex projects.

Recommending appropriate materials (e.g., specific grades of steel, aluminum, or alloys) based on the operational environment (temperature, corrosion, wear) and budget.

Ensuring all designs adhere to relevant industry standards, codes (like ASME, AWS), and safety regulations.

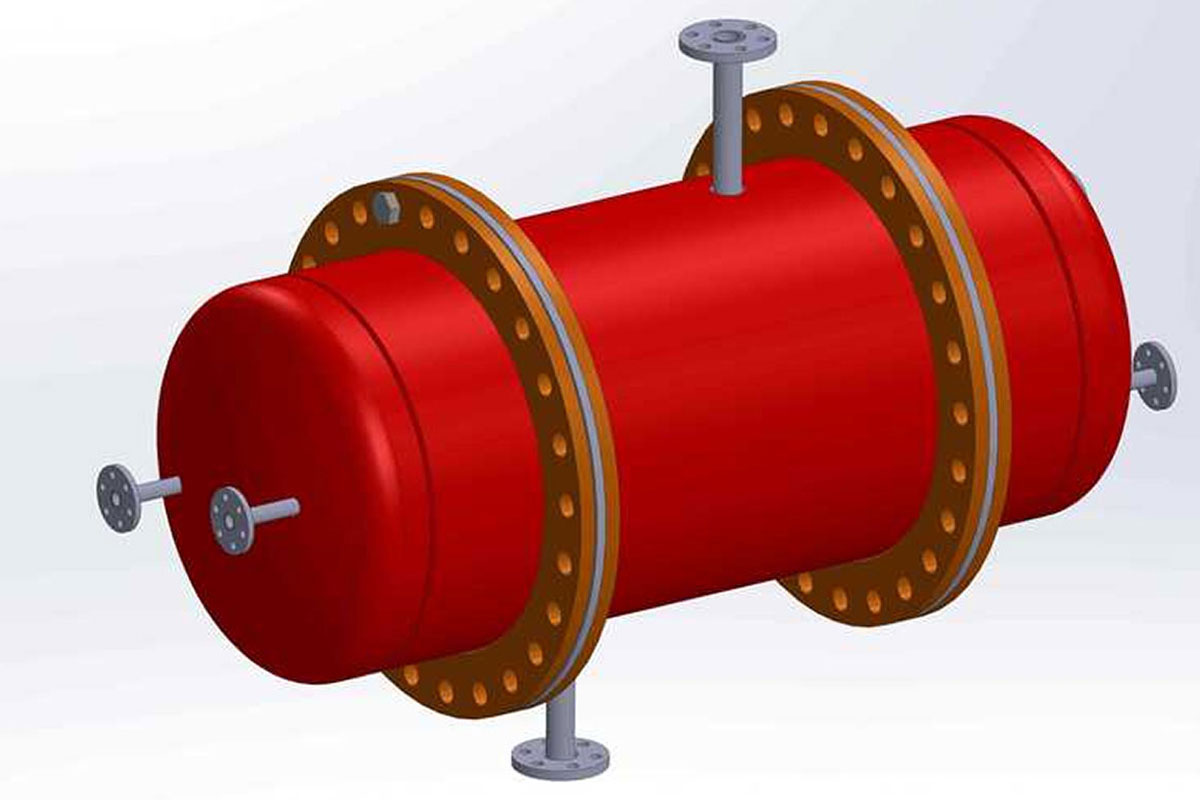

Computer-Aided Design (CAD) services are essential for the precise graphical representation of the final product. Fabricators utilize CAD software (like AutoCAD, SolidWorks, or Inventor) to create:

Providing precise dimensions, tolerances, and surface finishes needed for shop floor production.

Generating virtual prototypes for visualization, interference checks, and spatial planning. This is especially useful for complex assemblies or large-scale plant components.

Automatically generating comprehensive lists of all required parts, materials, and components.

By integrating these robust engineering and CAD capabilities, industrial fabricators can provide a complete, design-to-fabrication solution, minimizing errors, speeding up the production cycle, and ultimately delivering a high-quality, reliable, and compliant product.